manual fuel pump

A manual fuel pump is a mechanical device used to transfer fuel from a tank to an engine, relying on human operation rather than electric power. It ensures reliable fuel delivery in classic vehicles, agricultural equipment, boats, and small engines, offering simplicity and consistent performance for smooth operation.

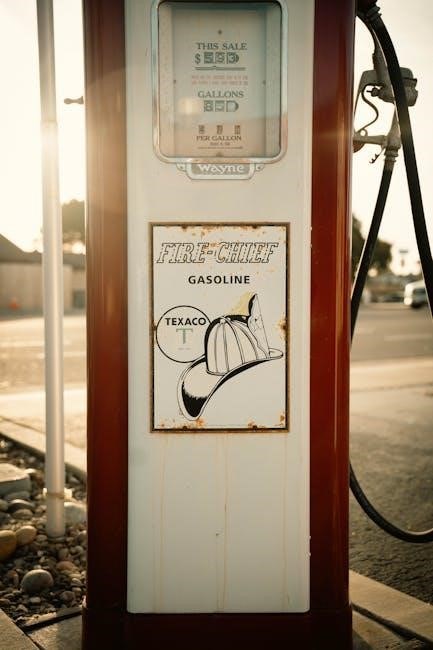

1.1 Definition and Purpose

A manual fuel pump is a mechanical device designed to transfer fuel from a storage tank to an engine or carburetor through manual operation. It operates using a lever, diaphragm, and valve system, creating suction and pressure to deliver fuel. Its primary purpose is to ensure a consistent fuel supply for combustion in engines, particularly in classic vehicles, boats, and agricultural equipment. Unlike electric pumps, manual fuel pumps rely on human effort, offering simplicity, reliability, and cost-effectiveness. They are essential for systems requiring precise fuel flow control and are often preferred for their durability and ease of maintenance in various applications.

1.2 Importance in Various Applications

Manual fuel pumps play a vital role in numerous applications where reliable fuel delivery is crucial. In classic and vintage vehicles, they preserve the authenticity and functionality of older engines. For marine vessels with carbureted engines, they ensure smooth operation in challenging environments. Agricultural machinery and small power equipment also benefit from their simplicity and durability. Additionally, manual fuel pumps are indispensable in remote or off-grid settings where electric power may be unavailable. Their ability to provide consistent fuel flow without reliance on electricity makes them a preferred choice for maintaining engine performance in diverse and essential applications, ensuring efficiency and dependability in critical operations.

Historical Perspective and Evolution

Manual fuel pumps trace their origins to early engine systems, evolving from simple hand-operated designs to more sophisticated mechanisms, playing a vital role in automotive and machinery advancement historically.

2.1 Early Development of Fuel Pumps

The manual fuel pump was first introduced in the early 20th century, emerging as a crucial component for engines lacking electric starters. Initially, these pumps were simple, hand-operated devices designed to draw fuel from tanks to engines. They relied on basic vacuum and pressure principles, using levers to create the necessary suction and pressurize fuel for delivery. Early designs were rudimentary, often employing diaphragms and valves to regulate fuel flow. Over time, these mechanisms evolved, becoming more efficient and reliable, which was essential for the operation of early internal combustion engines.

2.2 Role in Vintage and Classic Vehicles

Manual fuel pumps play a vital role in preserving the functionality and authenticity of vintage and classic vehicles. These pumps are integral to the engines of older cars, motorcycles, and agricultural machinery, where electric fuel pumps were not standard. They maintain consistent fuel flow, ensuring smooth engine operation without the need for modern electrical systems. Enthusiasts often prefer manual pumps for their reliability and simplicity, making them a cornerstone of classic vehicle restoration. Their continued use allows vintage engines to perform as originally intended, preserving the heritage of early automotive engineering and providing a connection to the mechanical roots of transportation history.

Working Principles of Manual Fuel Pumps

A manual fuel pump operates using a lever-driven mechanism that creates suction and pressure to transfer fuel from the tank to the engine, ensuring reliable delivery through diaphragm and valve action.

3.1 Vacuum and Pressure Mechanisms

A manual fuel pump generates suction through a vacuum mechanism, pulling fuel from the tank into the pump chamber. As the lever is operated, the diaphragm moves downward, creating a vacuum that draws fuel in. When the diaphragm returns to its original position, it pressurizes the fuel, forcing it through the outlet valve and into the engine system. This alternating cycle of vacuum and pressure ensures a steady fuel supply, maintaining consistent engine performance. The mechanism relies on precise valve operation to prevent fuel leakage and ensure efficient delivery, making it a reliable system for various applications.

3.2 Diaphragm and Valve Assembly Operation

The diaphragm and valve assembly in a manual fuel pump work in tandem to regulate fuel flow. When the lever is pressed, it moves the diaphragm downward, creating suction that draws fuel into the pump chamber. The intake valve opens to allow fuel entry, while the discharge valve remains closed. As the lever releases, the diaphragm returns to its original position, pushing fuel out through the discharge valve into the fuel line. The valves ensure fuel flows in one direction, preventing backflow and maintaining pressure. This synchronized operation ensures efficient fuel delivery, critical for smooth engine operation in various mechanical systems.

3.3 Suction and Pressure in Fuel Delivery

The manual fuel pump relies on suction and pressure to deliver fuel efficiently. As the lever is operated, the diaphragm creates suction, drawing fuel from the tank into the pump chamber. This suction is crucial for initiating fuel flow, especially in systems without electric assistance. When the diaphragm moves upward, it generates pressure, forcing fuel through the discharge valve and into the fuel line. The balance between suction and pressure ensures a steady fuel supply, preventing engine starvation during operation. This mechanism is vital for maintaining consistent fuel flow, especially in applications where reliable engine performance is essential, such as in classic vehicles or agricultural equipment.

Key Components of Manual Fuel Pumps

The manual fuel pump consists of a lever mechanism, diaphragm, valves, fuel lines, and connections, working together to create suction and pressure for fuel delivery.

4.1 Lever Mechanism and Its Function

The lever mechanism is a critical component of manual fuel pumps, responsible for initiating the pumping action. It operates by pivoting at its base, transferring motion to the diaphragm and valve assembly. This mechanism is typically connected to the camshaft or crankshaft, ensuring synchronized operation with the engine. As the lever moves, it creates suction, pulling fuel from the tank into the pump chamber. The lever’s design provides mechanical advantage, reducing the effort needed to operate the pump manually. Its reliable and straightforward functionality makes it essential for consistent fuel delivery in various applications, ensuring smooth engine performance and efficiency.

4.2 Diaphragm Construction and Role

The diaphragm is a vital part of manual fuel pumps, playing a central role in creating the suction and pressure necessary for fuel delivery. Constructed from durable, flexible materials, the diaphragm moves up and down within the pump chamber. When the lever mechanism activates, the diaphragm is pulled downward, creating a vacuum that draws fuel from the tank. As it returns to its original position, the diaphragm compresses the fuel, forcing it through the discharge valve into the engine system. This alternating motion ensures a steady fuel flow, making the diaphragm essential for the pump’s operation and reliability in various mechanical applications.

4.3 Valves and Their Significance

Valves play a crucial role in the operation of manual fuel pumps by regulating fuel flow and ensuring efficient delivery. Typically, there are two valves: the inlet valve and the outlet valve. The inlet valve opens to allow fuel to enter the pump chamber during the suction phase, while the outlet valve opens to release fuel into the engine system during the pressure phase. Proper valve operation ensures fuel flows in one direction, preventing backflow and maintaining consistent pressure. If the valves fail or become worn, fuel delivery is disrupted, leading to poor engine performance or stalling. Regular inspection and maintenance of these valves are essential to sustain the pump’s efficiency and reliability in various applications.

4.4 Fuel Lines and Connections

Fuel lines and connections are essential components of manual fuel pumps, ensuring fuel flows securely from the tank to the engine. These lines are typically made of durable materials like rubber or metal, designed to withstand fuel corrosion and pressure fluctuations. Proper connections are critical to prevent leaks and maintain consistent fuel delivery. Secure fittings and seals are used to connect the pump to the fuel tank and engine, minimizing the risk of fuel leakage. Regular inspection of fuel lines and connections is vital to identify signs of wear or damage, ensuring reliable performance and safety in operation; Maintaining these components is key to the overall efficiency of the fuel pump system.

4.5 Camshaft or Crankshaft Connection

A manual fuel pump is often driven by the camshaft or crankshaft, ensuring synchronized operation with the engine. The pump’s lever mechanism typically rides on the camshaft’s eccentric or cam lobe, converting engine motion into fuel flow; This connection allows the pump to operate in harmony with engine speed, delivering fuel consistently. The camshaft-driven design ensures reliable performance, while the crankshaft connection provides a direct power source for fuel delivery. Proper alignment and synchronization are crucial for efficient operation, making this connection vital for maintaining engine performance and fuel supply. This mechanical linkage is a cornerstone of manual fuel pump functionality and reliability.

Advantages of Manual Fuel Pumps

Manual fuel pumps offer simplicity, reliability, and cost-effectiveness, making them ideal for classic vehicles and small engines. They provide smooth, noiseless operation and consistent fuel delivery.

5.1 Simplicity and Reliability

Manual fuel pumps are renowned for their straightforward design and dependable performance. With fewer components compared to electric pumps, they minimize the risk of mechanical failure, ensuring consistent fuel delivery. Their simplicity reduces the need for complex diagnostics, making them easier to maintain and repair. This reliability is particularly beneficial in older vehicles and equipment where modern technology isn’t integrated. The lack of reliance on electricity further enhances their dependability, especially in situations where power sources may be unavailable. Overall, their uncomplicated mechanism and robust construction make manual fuel pumps a trustworthy choice for various applications.

5.2 Cost-Effectiveness and Efficiency

Manual fuel pumps offer significant cost savings due to their simple construction and minimal maintenance requirements. Unlike electric pumps, they don’t require advanced electronics or energy consumption, reducing both initial and long-term expenses. Their efficiency lies in delivering fuel directly without unnecessary complexity, ensuring optimal performance for engines. Additionally, the absence of electrical components means lower repair costs and extended lifespan. This makes them a budget-friendly option for classic cars and small machinery. Their fuel delivery system operates with minimal waste, enhancing overall efficiency and providing value for users seeking reliable, economical solutions for their fueling needs. These pumps are both cost-effective and energy-efficient.

5.3 Noiselessness and Smooth Operation

Manual fuel pumps are renowned for their quiet operation, as they lack the electrical components that often cause noise in other types of pumps. Their mechanical design ensures smooth fuel delivery without the hum or vibration associated with electric pumps. This makes them ideal for applications where noise reduction is essential, such as in classic vehicles or small boats. The absence of complex electronics also minimizes operational disruptions, ensuring a consistent and noise-free performance.

The pump’s diaphragm and valve system operate seamlessly, creating a steady flow of fuel without generating excessive noise. This smooth operation not only enhances user experience but also contributes to the overall reliability of the system. Additionally, the lack of electrical interference ensures quieter functioning, making manual fuel pumps a preferred choice for those seeking a peaceful and efficient fuel delivery solution.

Disadvantages and Limitations

Manual fuel pumps require physical effort, can deliver limited fuel volume, and may not integrate with modern engines, making them less practical for high-demand applications.

6.1 Limited Fuel Delivery Capacity

Manual fuel pumps often struggle to meet high fuel demand, making them less suitable for modern engines or high-performance applications. Their mechanical nature limits fuel flow rate and pressure, restricting their use in systems requiring consistent, high-volume delivery. Unlike electric pumps, they cannot automatically adjust output, leading to potential engine starvation during intense operation. This limitation makes manual pumps ideal for small engines or classic vehicles with lower fuel requirements but inadequate for contemporary vehicles or heavy machinery. Their simplicity, while reliable, sacrifices the ability to handle the higher fuel demands of advanced engine systems.

6.2 Requirement for Manual Effort

Manual fuel pumps require physical operation, demanding consistent human input to function. This can be inconvenient and tiring, especially during extended use. Unlike electric pumps, they lack automation, relying on manual actuation to draw fuel from the tank. This dependency on user effort makes them less efficient for applications requiring continuous fuel delivery. While suitable for small-scale or intermittent use, they are impractical for modern vehicles or high-demand systems. The need for manual intervention also increases the risk of inconsistent fuel flow, potentially affecting engine performance. This limitation underscores their suitability for niche applications rather than everyday use in advanced machinery.

6.3 Incompatibility with Modern Systems

Manual fuel pumps are often incompatible with modern fuel injection systems, which rely on electronic controls and higher pressure requirements. Their simple, mechanical design lacks the precision and adaptability needed for contemporary engines. Modern vehicles typically use electric fuel pumps that integrate seamlessly with computerized engine management systems, ensuring optimal fuel delivery. Manual pumps, with their diaphragm-based operation, cannot match the performance or compatibility of these advanced systems. This makes them unsuitable for vehicles equipped with modern fuel injection technology, limiting their use to older or specialized applications. Their inability to synchronize with electronic controls further highlights their obsolescence in today’s automotive landscape.

Maintenance and Upkeep

Regular maintenance ensures optimal performance and longevity of manual fuel pumps. Cleaning, lubrication, and inspection of diaphragms and valves are essential to prevent wear and ensure proper function.

7.1 Cleaning and Lubrication

Cleaning and lubrication are crucial for maintaining the efficiency of manual fuel pumps. Regularly inspect and clean the pump’s external and internal components to remove dirt and debris. Use a soft cloth and mild solvent to wipe down surfaces, ensuring no abrasive materials damage the parts. Apply a lightweight, fuel-resistant lubricant to moving components like the lever mechanism and valve assemblies. Proper lubrication reduces friction, prevents wear, and ensures smooth operation. Always follow the manufacturer’s recommendations for suitable cleaning agents and lubricants to avoid contamination and maintain optimal performance. Consistent maintenance helps prevent premature wear and extends the pump’s lifespan.

7.2 Diaphragm Replacement

Replacing the diaphragm in a manual fuel pump is essential when it shows signs of wear, such as cracks or loss of flexibility. Start by disconnecting the fuel lines and ensuring the system is drained. Remove the pump’s top cover to access the diaphragm assembly. Carefully detach the old diaphragm from the valves and pump chamber, taking note of its orientation. Install the new diaphragm, ensuring it is properly seated and aligned. Reassemble the pump, checking for any air leaks or misalignments. After replacement, test the pump by priming it several times to ensure consistent fuel flow and pressure. Regular diaphragm replacement prevents fuel leaks and maintains pump efficiency, ensuring reliable engine performance. Follow manufacturer guidelines for the correct replacement procedure and compatible parts.

7.3 Valve Inspection and Maintenance

Inspecting and maintaining the valves in a manual fuel pump is crucial for optimal performance. Start by disassembling the pump and examining the inlet and outlet valves for signs of wear, corrosion, or debris. Clean the valves using a soft brush and solvent to remove any buildup. If a valve is damaged or stuck, replace it with a compatible part. Ensure the valve seats are free from damage and properly seated to avoid fuel leaks. Lubricate the valves with a lightweight oil to ensure smooth operation. Regular maintenance prevents fuel flow issues and maintains the pump’s efficiency, ensuring reliable engine operation and preventing costly repairs. Always follow the manufacturer’s recommendations for valve care and replacement.

7.4 Routine Inspections

Routine inspections are essential for maintaining the functionality of a manual fuel pump. Regularly check for signs of wear, fuel leaks, or corrosion on the pump and its components. Inspect the diaphragm for cracks or damage, as this can lead to reduced fuel flow. Examine the valves for proper sealing and ensure they are free from debris. Clean the pump and surrounding areas to prevent contamination. Check fuel lines for cracks or damage and ensure all connections are secure. Inspect the lever mechanism for smooth operation and lubricate moving parts if necessary. Perform these checks every 3,000 to 5,000 miles or as recommended by the manufacturer to prevent breakdowns and ensure consistent performance.

Troubleshooting Common Issues

Manual fuel pumps can experience issues like fuel leaks, low pressure, or failure to prime. Diagnosing these problems early ensures smooth engine operation and prevents damage.

8.1 Failure to Prime the Pump

Failure to prime the manual fuel pump can occur due to air leaks, clogged fuel lines, or a malfunctioning diaphragm. Symptoms include difficulty starting the engine or rough idling. To resolve this, inspect the diaphragm for tears or damage and ensure all connections are tight. Cleaning or replacing faulty components can restore proper function. If the pump fails to create suction, check the valves for obstruction or wear. Addressing these issues promptly prevents engine performance problems and ensures reliable fuel delivery. Regular maintenance, such as cleaning and lubricating moving parts, can help avoid priming failures and maintain smooth engine operation.

8.2 Fuel Leaks and Their Causes

Fuel leaks in manual fuel pumps often arise from worn gaskets, damaged diaphragms, or loose connections. Over time, gaskets may degrade, allowing fuel to escape. A cracked or perforated diaphragm can also lead to leaks, as fuel bypasses the pump chamber. Additionally, improperly secured fuel lines or connections can cause seepage. Leaks may result in reduced fuel efficiency, engine performance issues, or even safety hazards. Inspecting and replacing worn components, tightening connections, and ensuring proper installation can mitigate these problems. Regular maintenance and prompt repairs are essential to prevent fuel leaks and maintain the pump’s reliability and efficiency.

8.3 Insufficient Fuel Pressure

Insufficient fuel pressure in manual fuel pumps can stem from a worn or damaged diaphragm, clogged fuel lines, or a malfunctioning check valve. A diaphragm that no longer seals properly fails to create adequate suction, reducing pressure. Clogged lines restrict fuel flow, while a faulty check valve allows fuel to return to the tank. Additionally, improper installation or worn gaskets can compromise the pump’s ability to generate pressure. Addressing these issues involves cleaning or replacing clogged components, inspecting the diaphragm for damage, and ensuring all connections are secure. Maintaining proper fuel pressure is crucial for consistent engine performance and preventing operational issues.

8.4 Diagnostic Steps and Solutions

Diagnosing issues with manual fuel pumps begins with identifying symptoms like insufficient pressure or leaks. First, inspect the diaphragm for cracks or wear, ensuring it’s sealing properly. Check valves for any blockages or damage, as faulty valves can disrupt fuel flow. Fuel lines should be examined for kinks or debris, which can restrict flow; If the pump fails to prime, air leaks in connections or a malfunctioning check valve may be the cause. Solutions include replacing damaged components, cleaning clogged lines, or adjusting connections to eliminate air leaks. Regular maintenance, such as lubricating moving parts and replacing worn seals, helps prevent issues and ensures reliable fuel delivery.

Installation and Upgrade Considerations

When installing or upgrading a manual fuel pump, ensure compatibility with the engine system and fuel type. Proper alignment and secure connections are crucial for efficient operation and safety.

9.1 Compatibility with Engine Systems

Ensuring compatibility with engine systems is crucial when installing a manual fuel pump. The pump must align with the engine’s fuel requirements, including pressure and flow rate specifications. Compatibility also involves checking the pump’s mechanical connection points, such as the camshaft or crankshaft, to ensure proper operation. Additionally, the fuel type (gasoline or diesel) and system design (carbureted or fuel-injected) must match the pump’s capabilities. Proper compatibility ensures efficient fuel delivery, prevents system damage, and maintains optimal engine performance. Always consult the engine’s specifications and the pump’s design parameters before installation to guarantee seamless integration and reliable functionality.

9.2 Installation Tips and Precautions

When installing a manual fuel pump, follow specific guidelines to ensure safety and functionality. Begin by disconnecting the battery to prevent accidental engine startup. Use appropriate tools to avoid damaging the pump or surrounding components. Ensure all fuel lines are securely connected to prevent leaks. Properly align the pump’s lever with the camshaft or crankshaft to maintain synchronization. Apply a thin layer of lubricant to moving parts for smooth operation. Avoid over-tightening connections, which can damage threads. Test the pump manually before starting the engine to check for leaks or irregular operation. Always refer to the manufacturer’s instructions for specific installation steps tailored to your engine type and pump model.

9.3 Upgrading for Enhanced Performance

Upgrading a manual fuel pump for enhanced performance involves selecting high-quality components tailored to your engine’s needs. Consider replacing the diaphragm with a durable, high-performance material like Viton for better resistance to wear and tear. Upgrade the valves to ensure smoother fuel flow and reduce pressure drops. Installing a fuel pressure regulator can help maintain consistent pressure, especially in high-performance engines. Additionally, upgrading fuel lines to stainless steel or high-pressure hoses can improve reliability. Ensure all modifications are compatible with your engine system and consult a professional to avoid potential incompatibilities. Proper testing after upgrades is crucial to verify performance improvements and prevent issues during operation.

9.4 Ensuring Efficiency and Safety

Ensuring efficiency and safety with a manual fuel pump involves maintaining proper fuel pressure and flow. Always use high-quality components and ensure compatibility with your engine system. Regular inspections of fuel lines and connections are crucial to prevent leaks and potential fire hazards. Proper installation is key to avoid misalignment or damage to the pump mechanism. Additionally, ensure the pump is well-lubricated and free from debris. Always follow manufacturer guidelines for maintenance and operation. Consulting a professional for complex upgrades or repairs can help prevent accidents and ensure optimal performance. Prioritizing safety measures guarantees reliable operation and protects against mechanical failure or fuel system damage.

Future Trends and Innovations

Future trends for manual fuel pumps include advancements in materials and technology, integrating modern innovations while maintaining mechanical simplicity for enhanced efficiency and durability in various applications.

10.1 Integration with Modern Technology

Manual fuel pumps are evolving to integrate with modern technology, such as sensors and electronic controls, to enhance performance and monitoring without compromising their mechanical simplicity. Innovations like fuel pressure sensors and digital diagnostics enable better fuel flow regulation and real-time monitoring, improving efficiency. Additionally, advancements in materials science are leading to more durable and corrosion-resistant components, ensuring longevity; Integration with electronic fuel injection systems allows manual pumps to work seamlessly in modern engines, offering a blend of traditional reliability and contemporary sophistication. These innovations ensure manual fuel pumps remain relevant in today’s advancing automotive landscape while maintaining their core mechanical advantages.

10.2 Potential Advancements in Design

Future manual fuel pumps may feature lightweight, high-strength materials like carbon fiber or advanced polymers to reduce weight and improve durability. Compact, modular designs could enhance versatility across different applications. Smart diaphragm materials, self-lubricating components, and optimized valve systems aim to minimize wear and extend lifespan. Energy-efficient mechanisms could reduce manual effort while maintaining consistent fuel flow. Additionally, eco-friendly designs might incorporate recyclable materials and lower emissions. These advancements aim to modernize manual fuel pumps, ensuring they remain efficient and sustainable in a competitive market, while retaining the simplicity that makes them a preferred choice for many users.