ideal logic combi 30 instruction manual

The Ideal Logic Combi 30 is a high-efficiency, A-rated boiler designed for compact spaces and easy installation. It combines reliable performance with advanced technology for optimal heating and hot water solutions.

This user-friendly boiler features a straightforward interface, making it ideal for both new and experienced users. Its eco-friendly design ensures reduced energy consumption and lower utility bills, promoting sustainability and comfort.

1.1 Overview of the Boiler and Its Features

The Ideal Logic Combi 30 is a compact, wall-mounted gas boiler designed for high efficiency and reliability. It features a built-in diverter valve, DHW plate heat exchanger, and a circulating pump for seamless operation. With a 24kW output, it delivers consistent heating and hot water. The boiler includes a user-friendly control panel, a pressure gauge, and a safety valve. It supports an 8-meter flue system and is A-rated for energy efficiency. Additional features include compatibility with timer kits and optional weather compensation controls, making it versatile for various household needs.

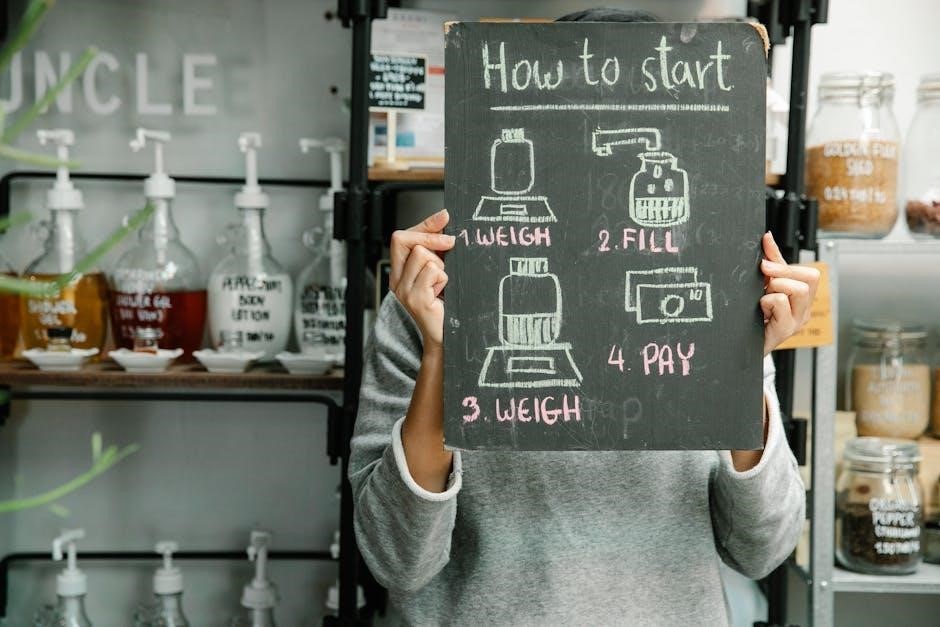

1.2 Importance of Reading the Instruction Manual

Reading the Ideal Logic Combi 30 instruction manual is crucial for safe and efficient operation. It provides essential guidelines for installation, usage, and maintenance, ensuring compliance with safety standards. The manual includes detailed diagrams and step-by-step instructions to help users understand boiler functions and troubleshoot common issues. Familiarizing yourself with the manual prevents misuse, extends the boiler’s lifespan, and helps maintain its warranty. Always refer to the manual before performing any adjustments or repairs to avoid potential hazards and ensure optimal performance.

Installation and Servicing Guidelines

The Ideal Logic Combi 30 requires precise installation and regular servicing to ensure efficiency and safety. Follow the manual’s step-by-step guide for proper setup and maintenance.

2.1 Pre-Installation Checks and Requirements

Before installing the Ideal Logic Combi 30, ensure the location meets safety and technical standards. Check for adequate ventilation, proper gas supply, and compatible existing plumbing. Verify the flue route adheres to the maximum 8m length and horizontal/vertical constraints. Ensure all electrical connections comply with local regulations and the boiler’s specifications. Review the manual’s Code of Practice sheet for critical safety guidelines. Conduct a site survey to confirm compatibility with the heating system and ensure all necessary tools and materials are available. Professional installation is highly recommended to guarantee compliance and optimal performance.

2.2 Step-by-Step Installation Instructions

Install the Ideal Logic Combi 30 in a well-ventilated area, adhering to local safety regulations. Begin by positioning the boiler on a suitable wall, ensuring level placement. Connect the flue system, respecting the maximum 8m length and horizontal/vertical constraints. Link the gas and water supplies, ensuring all connections are secure and leak-free. Install the mains cable, utilizing the pre-fitted 1.8m length. Connect electrical components, following the wiring diagram in the manual. Ensure the diverter valve, pump, and expansion vessel are correctly fitted. Activate the boiler and perform a test cycle to verify functionality. Always use genuine spare parts and follow the manual’s detailed instructions for a safe and efficient setup.

2.3 Post-Installation Tests and Safety Checks

After installation, perform a series of tests to ensure the Ideal Logic Combi 30 operates safely and efficiently. Check for gas and water leaks at all connections. Verify electrical connections are secure and meet safety standards. Test the flue system to ensure proper ventilation and compliance with the 8m maximum length. Activate the boiler and monitor its operation, checking for unusual noises or malfunctions. Ensure the pressure gauge reads correctly and all safety features, such as the diverter valve, function as intended. Refer to the manual for detailed procedures and consider professional verification for optimal safety.

Operating the Ideal Logic Combi 30 Boiler

Operating the Ideal Logic Combi 30 is straightforward with its user-friendly design. Use the control panel to regulate temperature, activate heating modes, and manage hot water settings efficiently, ensuring optimal performance and comfort.

3.1 Understanding the Control Panel and Display

The Ideal Logic Combi 30 features a user-friendly control panel with an LCD display, providing clear and real-time information about boiler status, temperature settings, and operating modes. The display shows current temperatures, error codes, and system notifications, ensuring easy monitoring. Navigation is straightforward, with buttons allowing adjustments to central heating and hot water temperatures. The control panel also enables access to advanced settings, such as timer programming and energy efficiency modes. Refer to the manual for detailed guidance on interpreting display messages and optimizing control panel functionality for personalized comfort and efficiency.

3.2 Setting Up and Adjusting Boiler Parameters

Setting up the Ideal Logic Combi 30 involves configuring parameters to suit your needs. Use the control panel to adjust central heating (CH) and domestic hot water (DHW) temperatures, with CH ranging from 30°C to 80°C and DHW up to 65°C. Set the boiler’s operating modes, including central heating only, hot water only, or both. Advanced settings allow customization of system pressure, weather compensation, and timer functions. Refer to the manual for detailed instructions on adjusting these parameters to optimize performance and comfort. Proper setup ensures efficient operation and meets specific household requirements. Always follow guidelines for safe adjustments.

3.3 Operating Modes (Central Heating and Hot Water)

The Ideal Logic Combi 30 offers three primary operating modes: central heating only, hot water only, or both. In central heating mode, the boiler provides warmth to radiators, while hot water mode delivers instant hot water on demand. When both are activated, it prioritizes hot water during a tap draw. The boiler automatically switches between modes based on demand, ensuring efficient energy use. This flexibility allows users to customize their comfort levels while maintaining energy efficiency. The control panel simplifies mode selection, making it easy to adapt to changing household needs.

Safety Precautions and Codes

The Ideal Logic Combi 30 includes essential safety features such as emergency shutdown and error code display. Always follow the manual’s guidelines to ensure safe operation and compliance with safety codes.

4.1 Boiler Safety Features and Emergency Shutdown

The Ideal Logic Combi 30 is equipped with multiple safety features to protect users and ensure reliable operation. These include automatic shutdown in case of system malfunctions, such as gas leakage or overheating. The boiler also features a pressure relief valve to prevent excessive pressure buildup. In an emergency, the system can be manually shut off using the emergency stop button located on the control panel. Additionally, error codes displayed on the screen help identify issues quickly, enabling prompt resolution and maintaining safety standards. Regular maintenance is crucial to uphold these safety features and ensure continuous performance.

4.2 Understanding Error Codes and Display Messages

The Ideal Logic Combi 30 boiler uses error codes and display messages to communicate system status and potential issues. Codes like 30C indicate specific faults, such as overheating, while others may signal issues like low water pressure or gas supply problems. The display provides clear guidance for diagnostics and troubleshooting. Always refer to the manual for detailed explanations of error codes and recommended solutions. Common codes include F1 (gas supply issue) or L (low pressure). If problems persist, contact a qualified professional for assistance. Regular checks can prevent many errors from occurring.

4.3 Emergency Procedures and Troubleshooting

In case of an emergency, immediately turn off the boiler and isolate the electrical supply. If you smell gas, open windows, evacuate the area, and contact a professional. For common issues like low pressure, repressurize the system using the filling loop. If the boiler locks out, reset it by pressing the reset button. Always refer to the manual for specific troubleshooting guidance. If problems persist, contact a certified technician to ensure safety and compliance with regulations. Regular maintenance can help prevent emergencies and extend the boiler’s lifespan.

Maintenance and Upkeep

Regular maintenance is essential for optimal performance and longevity. Ensure annual servicing by a certified professional, check flue integrity, and maintain proper ventilation. Always use genuine parts to meet safety and performance standards.

5.1 Regular Maintenance Tasks for Optimal Performance

Regular maintenance ensures the boiler operates efficiently and safely. Check the pressure gauge monthly and top up if necessary. Bleed radiators every 3-6 months to remove airlocks. Inspect the flue annually for damage or blockages. Ensure proper ventilation by keeping the boiler area clear. Descale the heat exchanger every 2 years, especially in hard water areas. Replace the expansion vessel if it shows signs of wear. Always use genuine Ideal Logic parts for replacements to maintain warranty and performance standards. Schedule annual servicing by a certified professional to ensure compliance and optimal functionality.

5.2 How to Service the Boiler (Professional Advice)

Annual servicing by a Gas Safe registered engineer is essential to maintain efficiency and safety. Inspect the heat exchanger, burner, and flue for damage or blockages. Clean the burner and combustion chamber to ensure proper gas flow. Check and replace the expansion vessel if necessary. Bleed the radiators to eliminate airlocks. Test the pressure relief valve and safety devices. Replace any worn-out seals or gaskets with genuine Ideal Logic parts. Adjust the gas valve and ignition system as needed for optimal performance. Ensure all electrical connections are secure and functioning correctly. Document all findings and recommend future maintenance as required.

5.3 Replacing Parts and Ensuring Compliance

When replacing parts on the Ideal Logic Combi 30, only use genuine or approved spares to maintain safety and performance. Always refer to the manufacturer’s specifications for compatibility. Turn off power and allow the system to cool before starting work. Drain the system if necessary and follow proper safety protocols. Ensure all replacements comply with local building codes and gas safety standards. Document the replacement process and retain records for future reference. Non-compliant parts may void the warranty or pose safety risks, so adherence to guidelines is crucial.

Technical Specifications and Compatibility

The Ideal Logic Combi 30 features compact dimensions, making it suitable for small spaces. It supports a maximum flue length of 8 meters and is compatible with optional timer kits and expansion modules for enhanced functionality.

6.1 Boiler Dimensions and Weight

The Ideal Logic Combi 30 boiler is designed to be compact and lightweight, making it ideal for installation in small spaces such as kitchens or utility rooms. Its dimensions are approximately 700mm (height) x 395mm (width) x 290mm (depth), ensuring it fits neatly into standard kitchen cupboards. Weighing around 28kg, the boiler is easy to handle during installation. Its lightweight and space-saving design contribute to a hassle-free installation process, while its robust construction ensures durability and reliability for long-term use.

6.2 Flue Installation and Maximum Length

The Ideal Logic Combi 30 boiler requires a flue system to safely vent combustion gases. The maximum flue length is 8 meters, ensuring compliance with safety standards. The flue kit includes necessary components like terminals and bends. Proper installation is critical to prevent gas leaks and ensure efficient operation. Always follow the manufacturer’s guidelines for flue installation and consult a professional if unsure. Improper flue installation can lead to safety hazards, so adherence to instructions is essential for optimal performance and safety.

6.3 Compatibility with Additional Features (e.g., Timer Kits)

The Ideal Logic Combi 30 supports integration with optional accessories like timer kits, enhancing user control and energy efficiency. Timer kits allow programming of heating schedules, optimizing comfort and reducing energy waste. Compatibility with these features ensures flexibility for users seeking advanced control. Proper installation of these accessories must follow the boiler’s manual to maintain warranty and safety standards. By integrating timer kits, users can streamline their heating system, ensuring it operates efficiently and meets their specific needs throughout the day.

User-Friendly Tips and Tricks

Optimize efficiency and comfort by utilizing the boiler’s timer kit and adjusting settings according to your lifestyle. Regularly updating parameters ensures peak performance and energy savings, enhancing overall user experience.

7.1 Maximizing Energy Efficiency

To maximize energy efficiency with your Ideal Logic Combi 30, ensure your home is well-insulated and use the boiler’s eco-mode. Adjusting the central heating temperature and hot water settings can significantly reduce energy consumption without compromising comfort. Regular maintenance, such as checking the flue and ensuring proper boiler servicing, also plays a crucial role in maintaining optimal efficiency. By following these tips, you can lower your energy bills and contribute to a more sustainable environment while enjoying consistent heating performance.

7.2 Customizing Settings for Personal Comfort

Your Ideal Logic Combi 30 allows you to tailor settings to suit your lifestyle. Adjust the central heating and hot water temperatures to your preference using the control panel. Utilize the timer function to schedule heating sessions, ensuring warmth only when needed. You can also customize operating modes, such as switching between central heating and hot water priority, to enhance comfort. These features ensure your boiler adapts to your daily routines, providing consistent comfort while maintaining efficiency.

7.3 Using the Boiler Timer Effectively

Maximize energy savings and convenience by using the Ideal Logic Combi 30 timer effectively. Program the boiler to activate heating and hot water only when needed, aligning with your daily schedule. Set specific times for heating sessions to avoid unnecessary energy use. This feature allows you to enjoy warmth and comfort while reducing waste. By optimizing the timer, you can balance convenience and efficiency, ensuring your home stays cozy without excessive energy consumption.

Troubleshooting Common Issues

Identify common issues like error codes and low pressure. Resetting the boiler often resolves these problems. Check the pressure gauge and top up if necessary.

8.1 Identifying and Resolving Common Faults

Common faults with the Ideal Logic Combi 30 include error codes like E1, E2, and L2, often indicating issues like low water pressure or flue problems. Resetting the boiler can resolve many issues. Check the pressure gauge and top up if necessary. If errors persist, consult the manual or contact a professional. Regular maintenance, such as annual servicing, helps prevent faults. Always refer to the troubleshooting guide for specific error codes and solutions to ensure safe and efficient operation.

8.2 Resetting the Boiler and Restoring Functionality

To reset the Ideal Logic Combi 30, switch it off, wait 10 seconds, and press the reset button until the light flashes. Release and allow the boiler to restart. If it fails to ignite, check for low water pressure or flue issues. Ensure the pressure gauge is at 1-2 bars and bleed radiators if necessary. If the problem persists, consult a professional. Resetting does not fix underlying faults, so always address root causes to restore functionality effectively and safely.

8.3 When to Contact a Professional

Contact a professional if the boiler displays persistent error codes, leaks water, or makes unusual noises. If resetting the boiler doesn’t resolve the issue or if you suspect gas leaks, turn off the supply and call a Gas Safe registered engineer. Never attempt repairs yourself, as this can void warranties or cause safety hazards. Professionals can diagnose complex faults, replace parts, and ensure compliance with safety standards, providing peace of mind and maintaining your boiler’s efficiency and reliability over time.